You don’t waste money on paper. You waste money on mismatched specs and unstandardized quotes. This guide shows you how to pick the right spec, run the pallet math, and compare landed cost—so you can request samples with confidence and secure a clean, comparable quote.

Snippet summary: Overpaying on wholesale copy paper usually happens when quotes aren’t normalized. Compare landed cost—unit price plus freight and accessorials—against the same specs: size (A4 or Letter), 20 lb / 80 gsm, brightness, opacity, and recycled/FSC needs. Test free samples for runability, then request case and pallet quotes using a standard template.

What actually drives wholesale copy paper cost

Spec drivers: weight, brightness, opacity, recycled content

When buyers say “quality,” they usually mean a mix of weight, brightness, and how much ink shows through.

One-row everyday recommendation

| Anwendungsfall | Gewicht | Helligkeit | Deckkraft | Anmerkungen |

|---|---|---|---|---|

| General office printing | 20 lb / ~80 gsm | 92 Helligkeit | Duplex-safe | Reliable for daily text documents |

20 lb (US) ≈ 80 gsm (metric). “Pounds” refers to basis weight; gsm is grams per square meter.

Brightness affects contrast. For everyday use, 92 brightness balances readability and cost.

Opacity influences show-through on duplex jobs. Higher opacity reduces visual bleed.

Recycled content (often post-consumer waste, PCW) and FSC-certified options support sustainability targets. Expect a price impact versus non-certified lines.

(For neutral definitions, see FSC, ISO brightness methods, and TAPPI testing concepts.)

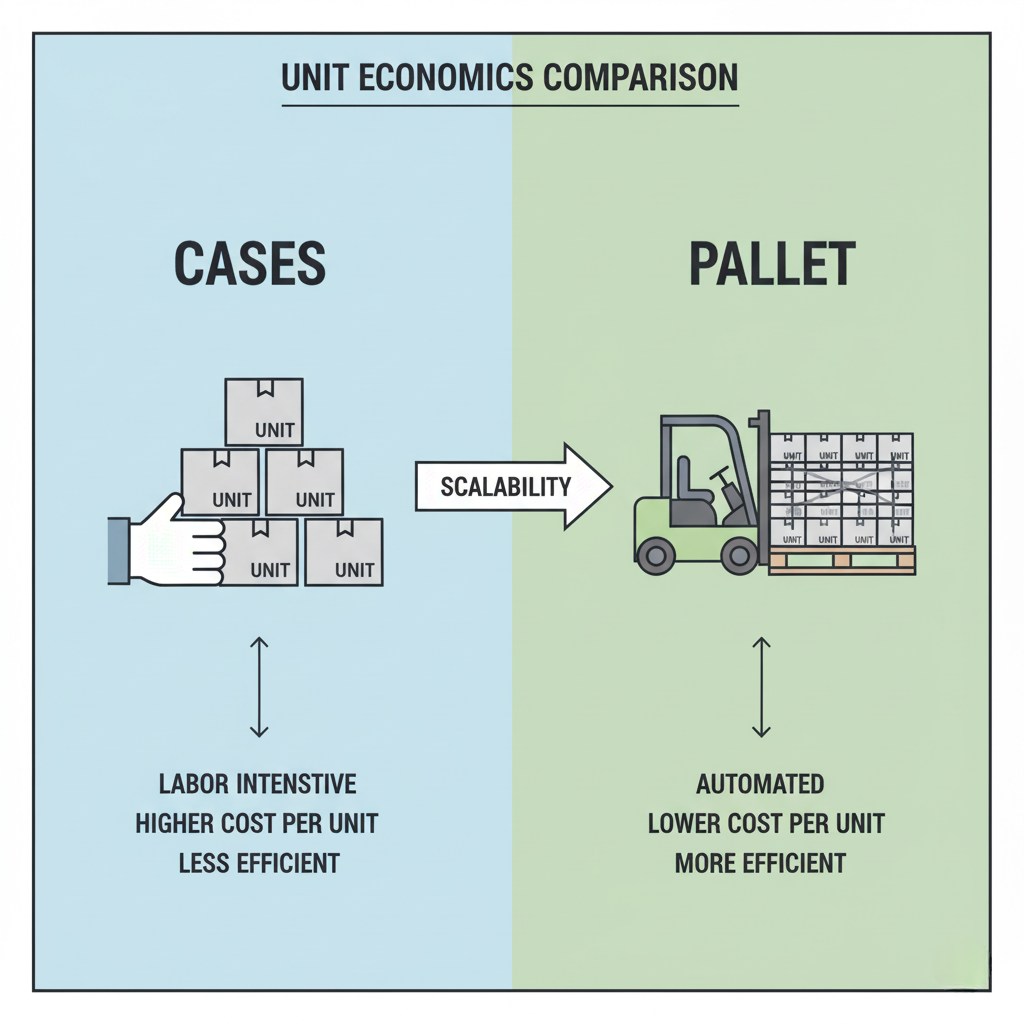

Volume drivers: case vs pallet, seasonality, freight

A typical case contains 10 reams × 500 sheets = 5,000 sheets.

Pallet pricing usually improves unit economics, but only if freight and accessorials don’t erase the discount.

Seasonality, mill schedules, and packaging changes can nudge pricing. Get quotes you can compare apples-to-apples.

Pick the right paper for your devices and jobs

A4 vs Letter: match your fleet

Check your fleet defaults and tray sizes. Many desktop printers default to Letter; multifunction copiers often support both. Standardize the size you actually use most to avoid waste and returns.

See A4 paper series brands for common A4 options if your fleet runs mixed sizes.

Weight & stiffness: when to stay at 20 lb / 80 gsm

Choose 20 lb / 80 gsm for everyday text, forms, and internal handouts. Consider heavier stocks only for heavy coverage, color blocks, or important client-facing materials. Heavier sheets raise cost and may reduce tray capacity.

Quick grid

Standard (20 lb / 80 gsm): everyday text, duplex okay, best total value

Heavier (24 lb / 90 gsm+): color coverage, external docs, stiffer feel

Brightness & opacity: keep show-through in check

92 brightness is the everyday sweet spot. If your jobs include small fonts or light color tints, higher brightness can help—but test it. Pair brightness with adequate opacity for duplex runs to avoid distracting show-through.

Sustainability options: recycled & FSC—what to request

If you require recycled or FSC-certified paper, ask for documentation, not just a badge.

Request:

- FSC certificate details and, where relevant, chain-of-custody info.

- Recycled content percent and whether it’s post-consumer waste (PCW).

- Product datasheet stating weight, gsm, brightness (ISO method), opacity, and caliper.

Pallet math without the headache

Cases per pallet, total sheets, and footprint

Ask your vendor for the exact cases-per-pallet for each SKU. It varies by brand, size, and packaging.

Simple formulas

Total sheets per pallet = cases per pallet × 5,000 sheets per case

Approximate storage footprint = pallet (L×W) × stacked height

Total gross weight = per-case weight × cases per pallet (request the figure—don’t assume)

Worked example (illustrative):

If a pallet carries 40 cases of Letter 20 lb paper:

Sheets = 40 × 5,000 = 200,000 sheets

Freight class, weight, and height depend on packaging; request these in the quote.

Storage & handling: keep paper print-ready

Store in a dry, climate-stable room; avoid damp basements.

Keep cartons wrapped until use to minimize moisture swings.

Acclimate paper to print-room conditions before long runs.

Avoid over-stacking that crushes corners; check packaging integrity on delivery.

Reorder cadence: match usage to buys

Estimate weekly usage in cases.

Choose monthly or quarterly deliveries.

Balance unit price gains from pallets with cash flow and storage.

Mini example:

If you use 4 cases/week, that’s 16–20 cases/month. Go monthly cases or a quarterly pallet if storage and cash flow allow.

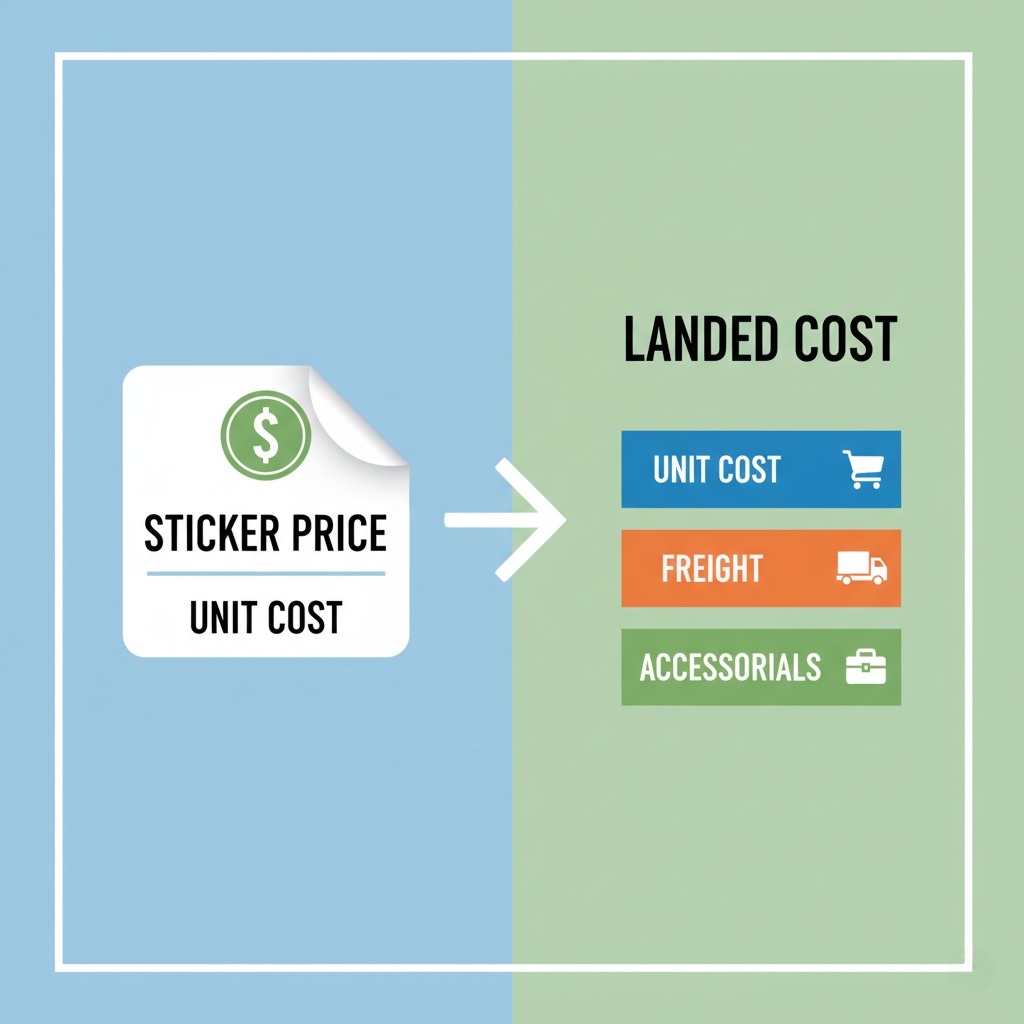

Compare quotes by landed cost, not sticker price

Standardize line items

| Field | What to ask for |

|---|---|

| SKU & spec | Size (A4/Letter), weight (20 lb / 80 gsm), brightness, recycled/FSC |

| Unit price | Price per case and any pallet price |

| Quantity | Cases and/or pallets |

| Freight | Itemized freight or “prepaid & add”; carrier class if available |

| Accessorials | Liftgate, inside delivery, appointment, residential, limited access |

| Taxes | Note exemptions; state if tax is included |

| Delivery window | Business hours, lead time, cutoff times |

| Substitutions | Allowed? If yes, define equivalent spec bounds |

| Total landed cost | Sum of all costs to your dock for this order |

One-liners to align definitions

Unit price: price per case at your stated quantity.

Freight: transportation charge; request an itemized figure.

Accessorials: extra services (e.g., liftgate or inside delivery).

Landed cost: everything above combined—your decision metric.

Common pitfalls (and how to avoid them)

- Mixed specs: Vendors quote similar, not identical SKUs. Provide your spec table, or accept a narrow substitution band.

- Hidden fees: Freight shows up later. Require freight and accessorials on the quote.

- Auto-substitutions: “Equivalent” brightness or recycled content. Allow substitutions only within defined bounds.

- Wrong size: A4 vs Letter mismatches. Confirm your fleet default in writing.

- No sample run: Looks fine on paper, jams on your device. Always sample first.

Proving runability before you commit

Sample first: a 6-print test plan

Use one ream per candidate SKU and run these prints:

- 10 single-page text jobs (simplex)

- 10 duplex text jobs

- 5 heavy-coverage pages (charts or dense color blocks)

- Long run: 200 simplex pages continuous

- Tray test: top tray and bypass/manual feed

- Curl/stack test: stack flatness after 24 hours

Log misfeeds/jams, visible dust, curl, and duplex show-through. Keep the best two SKUs for a second round if needed.

Datasheets to request

Ask vendors for a product datasheet showing:

- Basis weight / gsm (e.g., 20 lb / ~80 gsm)

- Brightness (state the method—ISO brightness is common)

- Opacity (predicts duplex show-through)

- Caliper (thickness)

- Whiteness (different from brightness)

- Sustainability: FSC status and recycled % (PCW) if applicable

Case vs pallet: when each makes sense

Choose cases when…

- You print under ~20 cases/month or storage is tight.

- You’re validating a new spec across multiple devices.

- Cash flow favors smaller, more frequent buys.

Choose pallets when…

- You have predictable usage and sufficient storage.

- Freight economics and accessorials are favorable.

- You’ve sampled and validated at least one qualifying SKU.

FAQs

Is 20 lb the same as 80 gsm?

Roughly, yes. They’re two systems for sheet weight. 20 lb (US) is approximately 80 gsm (metric) for standard copy paper.

Does 92 brightness look “white” enough for external docs?

For everyday prints, 92 brightness is fine. For color-critical materials, test a brighter sheet and review under your office lighting.

How many cases fit on a standard pallet?

It varies by brand and packaging. Ask your vendor for cases per pallet, height, and gross weight for the exact SKU.

What does FSC certification prove?

FSC relates to responsible forest management and, where applicable, chain-of-custody controls. Request documentation from the vendor.

Will recycled paper jam more?

Not necessarily. Run the sample test plan on your devices. Compare dust, curl, and duplex results to a non-recycled control.

Next steps

Get free samples — Try two or three SKUs that match your spec. Use the 6-print test and keep notes.

Get a quote — Send the quote template fields above to your vendors. Ask for case and pallet options with freight and accessorials itemized.