In the world of office procurement, the price of copy paper often appears to be a straightforward metric. Faced with tight budgets, many office managers and purchasing agents default to the most intuitive decision: select the option with the lowest price per ream. This common practice, however, is frequently a false economy. The sticker price of paper is merely the tip of a much larger financial iceberg, and failing to see the costs below the surface can lead to significant, unforeseen operational expenses.

Beyond the Ream: Why the Sticker Price of Paper is a Flawed Metric

Choosing office paper based solely on its per-ream cost is a tactical error that overlooks the systemic role paper plays within an organisation’s workflow. Office paper is not a passive consumable; it is an active component that interacts directly with your most critical hardware and your most valuable asset: your employees’ time. A ream of paper that costs a few dollars less can easily generate hundreds of dollars in indirect expenses.

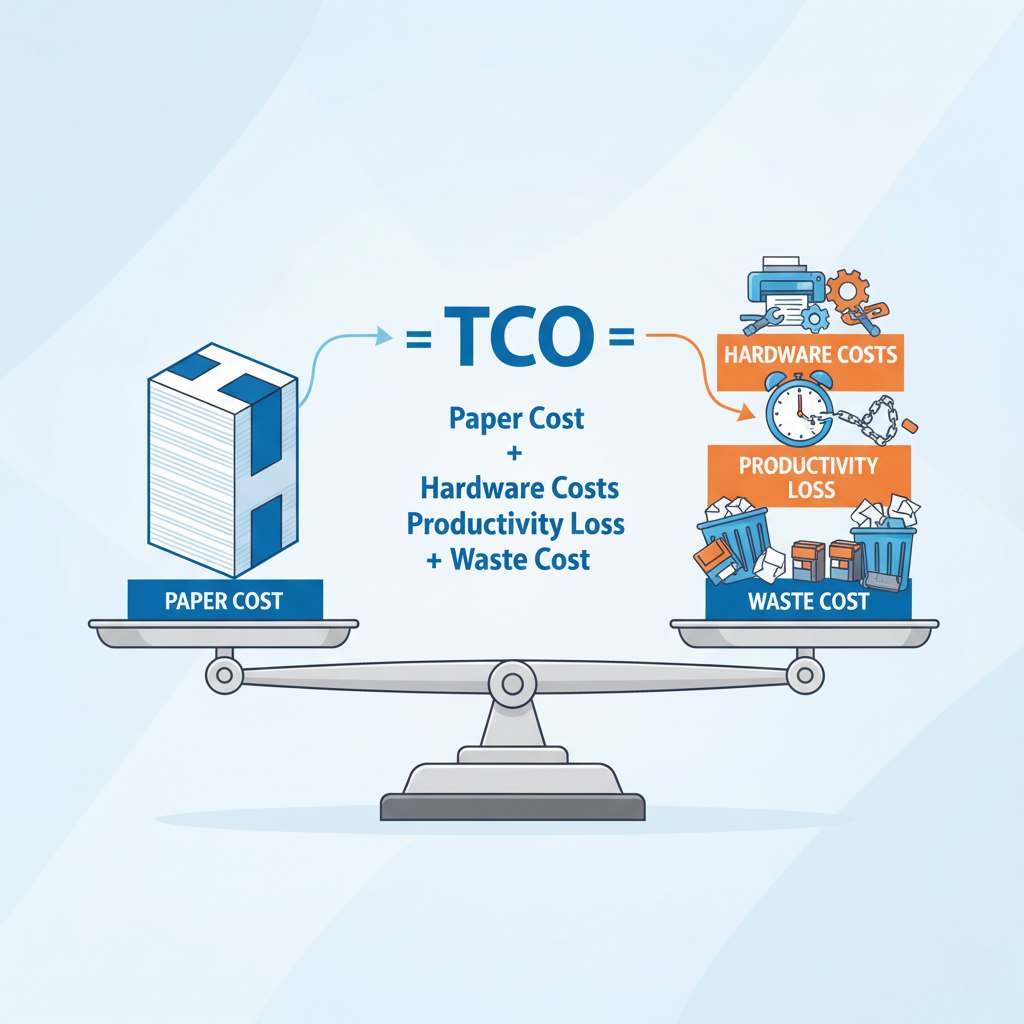

The fundamental flaw in the price-per-ream model is that it ignores the consequences of use. Low-quality paper, often characterised by inconsistent texture, higher dust content, and poor moisture control, introduces friction into the printing process—both literally and figuratively. This friction leads to a cascade of adverse financial events that are never itemised on the supplier’s invoice. By shifting the evaluation from “How much does this cost to buy?” to “How much does this cost to use?“, the TCO model provides a far more accurate and insightful basis for making a financially sound procurement decision. The thesis is straightforward: cheaper paper often results in a higher Total Cost of Ownership, which directly impacts the bottom line.

The Hidden Costs: Key Pillars of Paper’s Total Cost of Ownership

To accurately assess the TCO of office paper, it is essential to deconstruct the hidden expenses into three primary pillars. These factors represent the most significant and frequent ways that low-grade paper silently drains an organisation’s resources.

2.1. Factor 1: Accelerated Hardware Depreciation and Maintenance

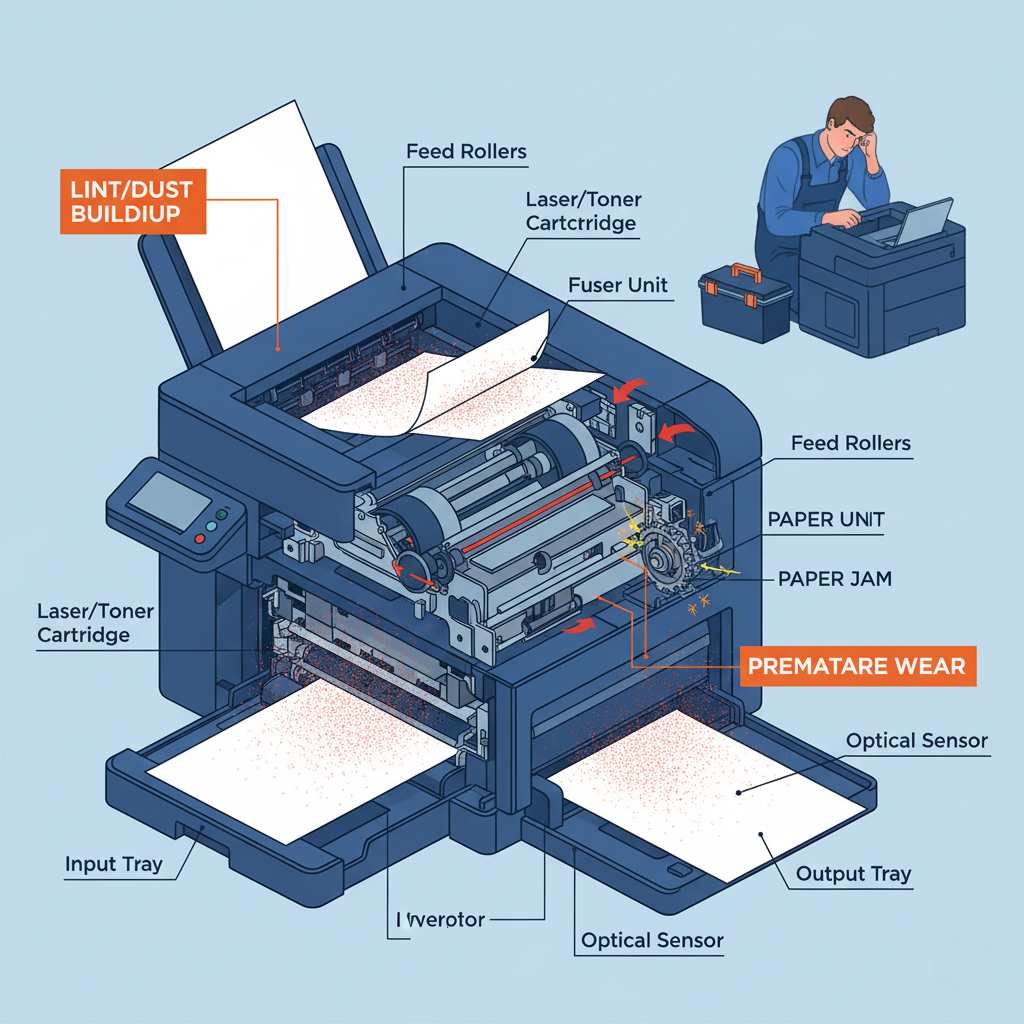

High-quality office printers and multifunction devices represent a significant capital investment. The quality of the consumables used directly influences the longevity and reliability of this equipment. Low-quality copy paper is a primary contributor to premature hardware failure and increased maintenance needs.

This occurs for two main reasons. First, cheaper paper tends to have a higher lint and dust content due to less refined manufacturing processes. As each sheet passes through the printer, it sheds microscopic paper particles that accumulate on critical components, such as rollers, sensors, and fuser units. This buildup can lead to misfeeds, spotting on pages, and eventually, component failure, necessitating costly service calls. Second, inconsistencies in paper thickness, texture, and rigidity can place undue stress on the printer’s mechanical parts, accelerating wear and tear and shortening the machine’s effective operational lifespan.

2.2. Factor 2: The Unseen Expense of Lost Productivity

The most significant hidden cost is the cumulative impact of lost employee productivity. A paper jam is never just a minor inconvenience; it is a complete workflow interruption. The time an employee spends clearing a jam, re-initiating a print job, and refocusing on their original task is time that is irretrievably lost.

Consider the ripple effect. A single jam can take an employee five to ten minutes to resolve. If this occurs multiple times a day across several departments, the lost hours quickly accumulate. For high-volume printing environments, such as legal offices or accounting firms, frequent jams can delay the preparation of critical documents, impacting client deadlines and overall business agility. This operational drag represents a substantial, albeit often unmeasured, labour cost directly attributable to the choice of paper.

2.3. Factor 3: The Financial Impact of Waste and Poor Quality

Poor print quality is another direct consequence of using substandard paper, resulting in significant material waste. When paper has low brightness or poor opacity, text and images can appear dull, and printing on both sides (duplexing) may result in show-through, rendering the document unprofessional. Similarly, poor ink and toner absorption can cause smearing and fuzzy text.

Every document that must be reprinted due to these issues incurs a triple cost: the cost of the wasted sheet of paper, the cost of the wasted ink or toner, and the cost of the employee’s time to manage the reprint. For large print jobs, such as client proposals or marketing materials, a single instance of poor output can result in hundreds of wasted pages and a significant financial loss. This waste directly counteracts the initial savings realised from purchasing cheaper paper.

The TCO Calculation: A Practical Framework for Your Business

Transitioning from a conceptual understanding to a quantitative analysis is key to leveraging TCO in your procurement strategy. While a precise calculation requires internal data, the following framework and hypothetical example illustrate how to approximate the TCO for your organisation.

3.1. The TCO Formula at a Glance

3.2. A Hypothetical Example: A 50-Employee Office

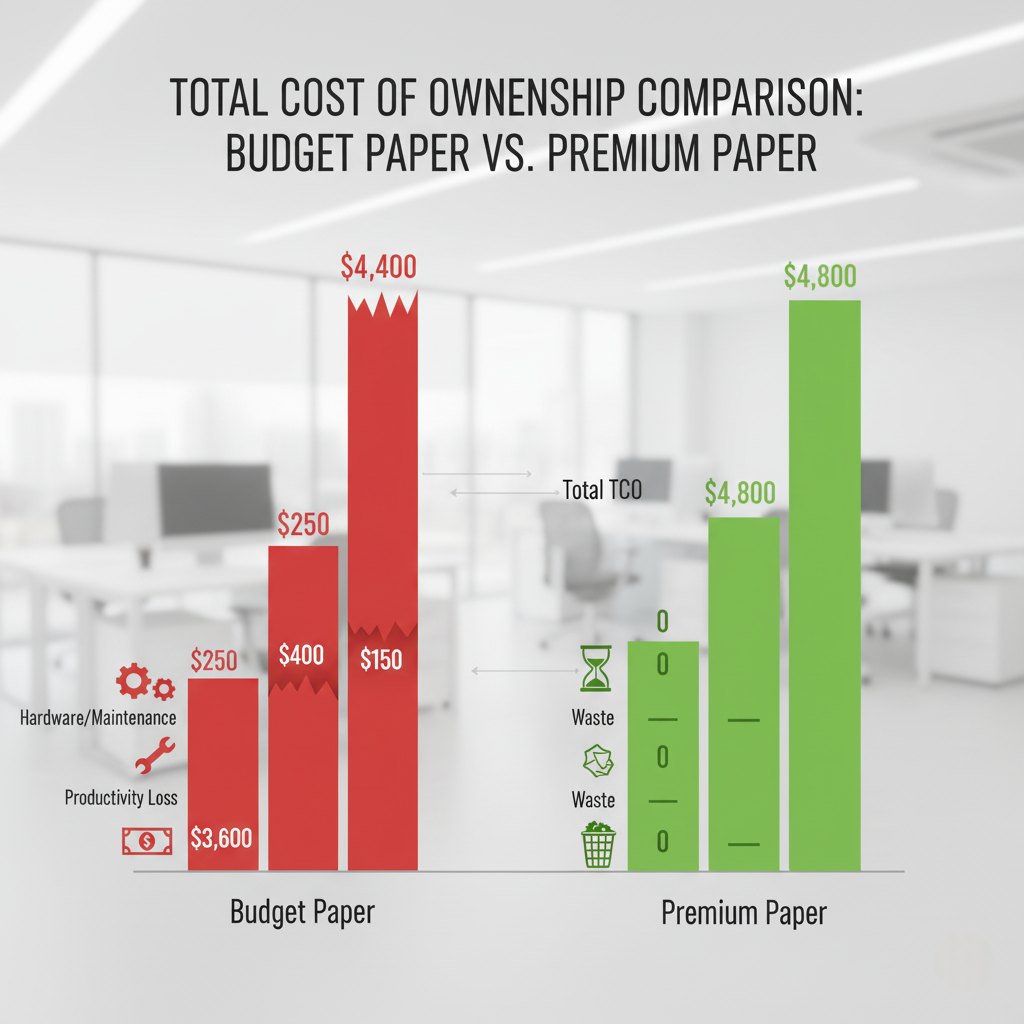

Let’s apply this framework to a typical 50-employee office that uses 10 cases of paper per month. They are choosing between “Budget Paper” at $30/case and “Premium Paper” at $40/case, which is 99.9% jam-free.

Annual Cost of Paper:

- Budget Paper: 10 cases/mo × 12 mos × $30/case = $3,600

- Premium Paper: 10 cases/mo × 12 mos × $40/case = $4,800

Hardware & Maintenance Cost (Estimated):

- Assume the Budget Paper causes one extra $150 service call per year and slightly reduces printer lifespan, resulting in an additional $100 in annual depreciation costs. Total: $250.

- Premium Paper is assumed to cause no extra costs. Total: $0.

Productivity Loss Cost:

- Assume the Budget Paper causes an average of 5 jams per week. Each jam takes 6 minutes (0.1 hours) to fix. The average employee wage is $25/hour.

- 5 jams/wk × 52 wks = 260 jams/year

- 260 jams × 0.1 hours/jam = 26 hours of lost time

- 26 hours × $25/hour = $650 in annual productivity loss.

- Premium Paper (99.9% jam-free) is assumed to have negligible productivity loss. Total: $0.

Waste Cost (Estimated):

- Assume a 2% reprint rate with the Budget Paper due to quality issues. This results in the wastage of 2.4 cases of paper annually, plus the associated ink/toner—estimated annual cost: $120.

- Premium Paper is assumed to have a negligible waste rate. Total: $0.

Final TCO Comparison:

- Budget Paper TCO: $3,600 (Paper) + $250 (Hardware) + $650 (Productivity) + $120 (Waste) = $4,620

- Premium Paper TCO: $4,800 (Paper) + $0 + $0 + $0 = $4,800

In this realistic scenario, the initial $1,200 savings from the budget paper nearly vanish when indirect costs are factored in. A slightly higher jam rate or more expensive employee time would easily make the premium paper the more cost-effective choice.

From Theory to Practice: How Investing in Quality Paper Reduces TCO

The TCO calculation makes it clear: investing in higher-quality paper is a strategic decision that pays measurable dividends. High-grade paper is engineered to actively reduce the hidden costs that inflate your Total Cost of Ownership.

By selecting a paper with superior formation and precise cutting, you significantly reduce the risk of dust and lint buildup, thereby extending the life of your printers and decreasing the frequency of maintenance. A product that is specifically designed for 99.9% jam-free performance, like our premium line, directly addresses the productivity pillar. It transforms the hundreds of hours potentially lost to jams across your organisation into productive, value-generating work. Furthermore, superior brightness, opacity, and toner adhesion ensure that every print is crisp, professional, and right the first time, virtually eliminating the costs associated with waste and reprints.

While the initial investment in quality paper may be marginally higher, the evidence from a TCO analysis is conclusive. It is the most financially responsible choice for any business that values operational efficiency, asset longevity, and employee productivity. By making an informed decision based on total cost rather than initial price, you are not just buying paper; you are investing in a smoother, more cost-effective, and more productive workplace.