This guide is written for B2B procurement, finance, facilities, and IT stakeholders. It outlines the must-have sections of a defensible RFP, the pricing architecture vendors should follow, and the service levels that protect operations. It is not legal advice.

By locking in the methodology, buyers compare the true delivered cost rather than the attractive base prices that balloon with fees.

1. Who This RFP Is For—and What Outcomes It Should Guarantee

A copy paper RFP should do more than request quotes. It should reduce the total cost of ownership (TCO), prevent operational disruption, and create a fair comparison across suppliers. For multi-location organizations, the document must align procurement strategy with service realities: predictable delivered pricing, dependable on-time performance, and consistent product quality that minimizes jam rates, waste, and returns.1.1 Business Context & Constraints

Most enterprises face a familiar set of constraints, including distributed ship-to locations, seasonal spikes (such as fiscal year-end, school calendars, and marketing campaign peaks), sustainability targets, and ERP or punch-out requirements. The RFP should state these constraints explicitly, so bidders price and plan against the world the buyer actually operates in.2. Define the Scope: Volumes, SKUs, and Service Footprint

Scope clarity is the strongest guardrail against “gotcha” costs and performance failures. Vendors can only provide accurate quotes when the bill of materials and service footprint are unambiguous.2.1 Volume Profile & Ship-To Matrix

Provide a 12-month volume table by site, showing average monthly demand and peak months. Separate small parcels from LTL/palletized lanes. Note lift-gate requirements, loading dock availability, and any appointment scheduling rules. If some sites accept only breakpacks or require inside delivery, please note this here.2.2 SKU Standardization & Acceptable Alternatives

Standardize on core SKUs by size (Letter, Legal, A4), basis weight (20 lb vs 24 lb), brightness (92 vs 96), and recycled content. Where acceptable, specify brand-equivalent substitutions and define the pre-approval process. A simple equivalency matrix (manufacturer, item, attributes, allowed substitute) prevents ad-hoc swaps that create print issues or user complaints.2.3 Packaging, Storage, and Environmental Conditions

Spell out carton strength (burst or ECT targets), palletization standards, stretch-wrap expectations, and humidity controls. If sites run high-speed laser fleets or duplex by default, this is the place to state minimum paper flatness or moisture guidelines to reduce curl, jams, and bleed-through.3. Pricing Architecture: How Vendors Must Quote

Normalizing the quote format is the only way to compare bids “apples to apples.” Require that every vendor populate a consistent pricing table and disclose all adjusters.3.1 Unit Tiers & Breaks

Define unit tiers clearly: Ream, case, carton, and pallet. Require stepped discounts at specified thresholds and list any minimum order quantities (MOQs) per ship-to location. Where vendors propose subscription or standing orders, state how the discount applies and whether the price holds spans the full term.3.2 Cost-Per-Sheet Methodology

Cost-per-sheet is a simple but powerful equalizer. Ask vendors to express pricing in cost-per-sheet after freight and waste factors. The calculation below can be pasted into your RFP:| Component | Example Value | Бележки |

|---|---|---|

| Case price (10 reams x 500 sheets) | $49.00 | Vendor’s list or net price |

| Sheets per case | 5,000 | 10 × 500 |

| Expected waste/jam factor | 1.5% | Buyer-defined or test-derived |

| Freight per case (delivered) | $2.00 | Blended across lanes or lane-specific |

| Cost per sheet (delivered) | ((49.00 ÷ 5,000) × 1.015) + (2.00 ÷ 5,000) = $0.0105 | Use four decimals for precision |

3.3 Freight, Fuel, and Accessorials

Require vendors to disclose whether prices are delivered or FOB, the fuel index used, trigger points for surcharges, and all accessorials (including residential, inside delivery, lift-gate, appointment windows, and limited access). Ask for lane-level freight assumptions if large sites receive palletized loads.3.4 Price Protection & Adjustments

Define the Index (pulp, fuel, or composite) that may drive increases, review cadence (e.g., quarterly), caps per period, and notice periods. Include a price-down mechanism for index declines. Require a transparent formula rather than discretionary adjustments.3.5 Rebates, Credits, and Payment Terms

List acceptable early-pay discounts, volume rebates, shortage/damage credit timelines, and net terms. If rebates are offered, specify the accrual basis and auditability. State the evidence required for credit claims (photos, POD notes, return authorization) and the target resolution time.4. SLAs That Cut Operational Risk

Service levels transform a price into a reliable supply program. They should be measurable, auditable, and tied to remedies.4.1 Fill Rate & OTIF (On-Time, In-Full)

Set OTIF targets by lane type (parcel vs LTL) with reporting cadence (monthly). Define what counts as “on time,” the acceptable lead times, and the backorder management policy. Specify whether substitutions require pre-approval and how buyers can indicate partial substitutions.4.2 Delivery Windows, Cutoffs, and Holiday Calendars

Require daily order cutoffs by time zone, delivery windows by site (e.g., 9:00 a.m.–3:00 p.m.), and published holiday calendars. Spell out the appointment policy for big sites and the penalty or credit structure for missed windows.4.3 Quality & Jam-Rate Thresholds

Define jam-rate thresholds (e.g., jams per 10,000 sheets) and specify the test conditions, including device type, environment, and document profile. Describe the sampling plan for inbound QC, lot traceability requirements, and the non-conformance workflow. Establish the replacement SLA for damaged or defective goods.

4.4 Support SLAs & Escalation Paths

Require named account contacts, support hours, first-response and resolution SLAs, and a clear escalation path including executive sponsorship. For claims and credits, mandate turnaround targets and the documentation templates that vendors must accept.5. Compliance, Sustainability, and Records Requirements

Compliance sections protect brand, policy, and long-term records. They also clarify how sustainability objectives fit into procurement without inflating cost.5.1 Certifications & Materials

Ask vendors to state the recycled content percentages and list applicable certifications (e.g., FSC, PEFC, SFI), as well as chain-of-custody documentation. Define whether certifications are mandatory or preferred and how substitutes are handled if certified stock is temporarily unavailable.5.2 Records & Archival Standards

For records-intensive functions (such as legal, finance, and medical), specify archival expectations, including the use of acid-free paper and duplex suitability. Reference recognized paper characteristics that preserve legibility and prevent degradation in long-term storage.5.3 Data, Privacy, and E-Procurement

If the program utilizes EDI or punch-out, it requires supported document types (PO, ASN, invoices), specific data fields, and established testing timelines. Where vendors interface with PII or financial systems, state the baseline security frameworks (e.g., SOC or ISO posture) you expect.6. Evaluation Scorecard & Weighting Model

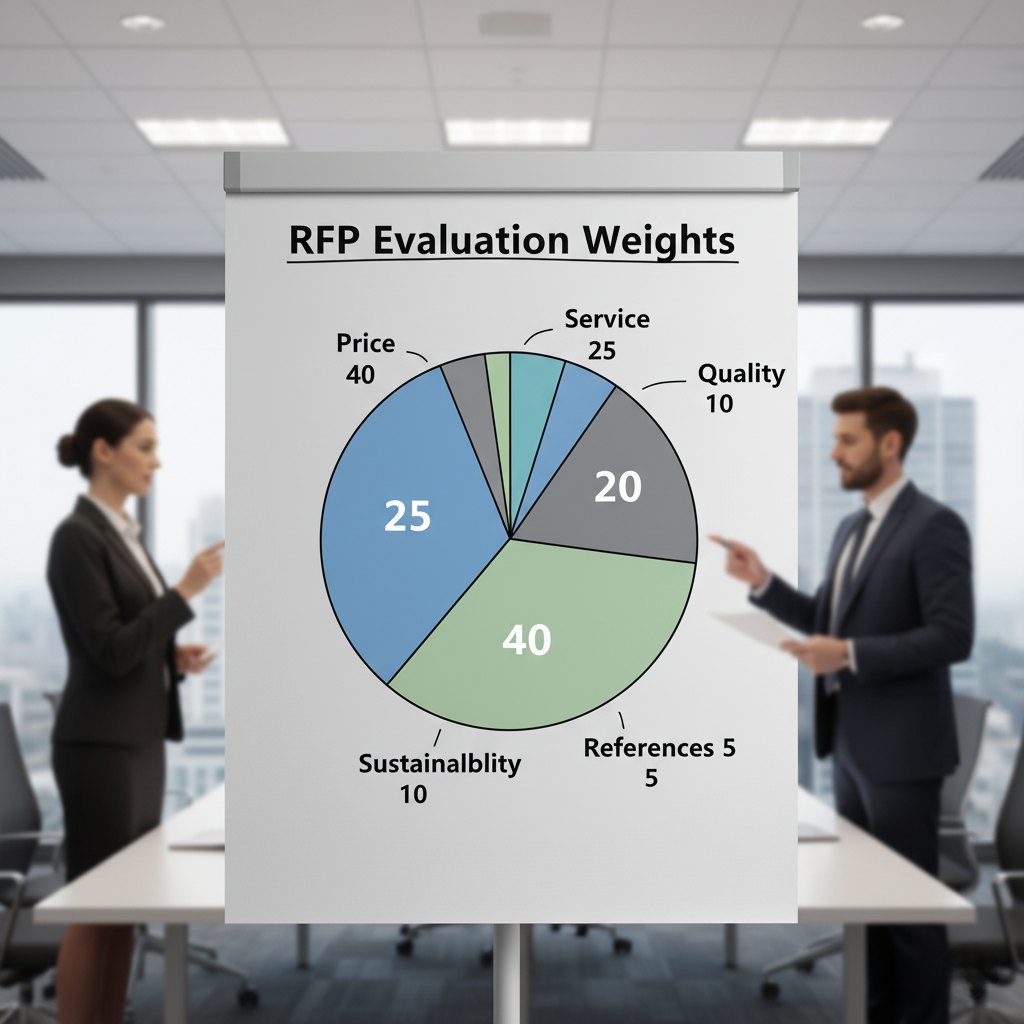

Transparent scoring makes awards defensible and improves vendor behavior over the contract term.6.1 Example Weights

Use a simple weighting model and publish it in the RFP so vendors aim at what matters:| Criterion | Тегло |

|---|---|

| Price (delivered cost-per-sheet) | 40 |

| Service SLAs (OTIF, cutoffs, support) | 25 |

| Quality (jam-rate, defect handling, packaging) | 20 |

| Sustainability & Compliance | 10 |

| References & Fit | 5 |

| Total | 100 |

6.2 Pilot & Proof-of-Performance

Before awarding the full amount, run a time-boxed pilot across representative sites. Track OTIF, jam rates, damage/shortage claims, and credit turnaround. Tie the final award or contract start to meeting pilot thresholds. This de-risks transitions and validates vendor claims without relying on slide decks.6.3 Reference Checks & Site Audits

Ask for references that match your size and vertical—probe for multi-site experience, surge handling, and root-cause analysis rigor on prior incidents. Where practical, request a warehouse or cross-dock tour—audits reveal whether vendors can actually execute the SLAs they quote.7. Mandatory Vendor Questionnaire (Paste Into Your RFP)

A structured questionnaire forces comparable responses and speeds evaluation. The prompts below are designed for yes/no clarity with short evidence requests.7.1 Company Profile & Capacity

Provide the current footprint, including warehouses, cross-docks, and coverage by state or region. State average and peak daily outbound capacity (cases and pallets). Describe contingency plans for surge periods and weather disruptions.7.2 Quality Assurance & Testing

Outline incoming QC protocols, sampling rates, and lot traceability. List the test methods used to validate jam-rate, curl, and opacity. Provide the non-conformance workflow and target resolution times.7.3 Substitution & Discontinuation Policy

Define your acceptable-alternative process, including pre-approval steps. Attach an equivalency matrix for core SKUs (size, weight, brightness, recycled content). Please explain your product sunset plan and associated notification timeline.7.4 Claims, Credits, and Dispute Resolution

State timelines for filing damage/shortage claims and evidence requirements. Confirm auto-credit thresholds and expected credit issuance SLAs. Provide escalation contacts for unresolved disputes.8. Implementation & Change Management Plan

Even the best price fails if rollout is chaotic. The RFP should request a pragmatic plan that operations can live with.8.1 SKU Rationalization & Communication

Ask vendors to propose a rationalized SKU set and a change management plan, including who will be trained, how signage and internal catalogs will be updated, and how legacy inventory will be phased out to minimize waste.8.2 Systems Integration

Define ERP item setup requirements (attributes, units of measure, vendor part numbers), mapping for EDI or punch-out catalogs, and invoice testing. Require sample transactions as part of the vendor onboarding process.8.3 Demand Planning & Safety Stock

Request a demand plan by site with safety stock rules, seasonality assumptions, and substitution logic for constrained items. This gives operations confidence that run-rate demand will not be choked when peak periods arrive.9. What Happens After You Issue the RFP

The most effective RFPs also script the road ahead, so suppliers understand timelines and buyers avoid last-minute fire drills.9.1 Timeline & Communications Plan

Publish the calendar at the front of the RFP: Q&A window, addenda cutoffs, bid due date, shortlist notifications, pilot start and end dates, and anticipated award date. Require vendors to acknowledge receipt of addenda to eliminate “we didn’t see that” surprises.9.2 Award Criteria & Negotiation Plan

Explain how best-and-final offers will be requested, how price holds work during contracting, and how index-based adjustments will be written—state service credits or remedies for missed SLAs and the conditions for renewal. Where multiple vendors are awarded, clarify territory or lane splits to avoid overlaps.Quote Normalizer (Pasteable Section)

This single table turns a heterogeneous set of quotes into a comparable grid. Instruct vendors to fill it.| Field | Required Input |

|---|---|

| Unit pricing tiers: Ream, case, carton, pallet | |

| Delivered vs FOB | Delivered price or FOB + freight table |

| Freight & fuel | Index used, trigger points, accessorials list |

| OTIF target | % by lane with reporting cadence |

| Order cutoffs: Daily cutoff by time zone | |

| Holiday calendar: An Annual published schedule | |

| Jam-rate threshold: Jams per 10,000 sheets and test conditions | |

| Price protection | Review cadence, caps, notice periods |

| Credits | Damage/shortage timelines and auto-credit policy |

| Payment terms: Net terms and early-pay discounts | |

| Substitutions: Pre-approval workflow and equivalency matrix | |

| Устойчивост | Certifications and recycled content percentages |