Why paper standardization matters for global teams

Organizations that operate across regions inherit different page sizes, legacy templates, and device defaults. When formats diverge, minor mismatches cascade into wasted prints, pagination errors, avoidable help-desk tickets, emergency purchases, and inconsistent records. A single, written standard minimizes these risks by aligning document templates, print settings, procurement SKUs, and supplier commitments.

The hidden costs of mixed formats

Reprints and waste: Truncation at margins or last-page overflow leads to duplicate runs and unnecessary paper/ink waste.

Service friction: Misfeeds and jam-clear procedures increase downtime for shared devices, especially in high-volume environments.

Template sprawl: Multiple variants for the same form (Letter, A4, Legal) fragment governance and QA.

Inventory complexity: Parallel SKUs (Letter and A4) split demand, raise holding costs, and create stockouts where the “wrong” format is abundant.

Record integrity: Page breaks that differ by region complicate regulatory or legal reviews.

Cross-border document exchange

Teams frequently convert quotations, statements of work, and contracts across jurisdictions. Without a unified policy, a document created in one region reflows unpredictably in another, undermining brand consistency and professional presentation.

Downstream impact

Facilities plan capacity around predictable usage; IT sets defaults in drivers and print servers; procurement negotiates packaging and palletization. Standardization reduces variability for all three functions and stabilizes service levels.

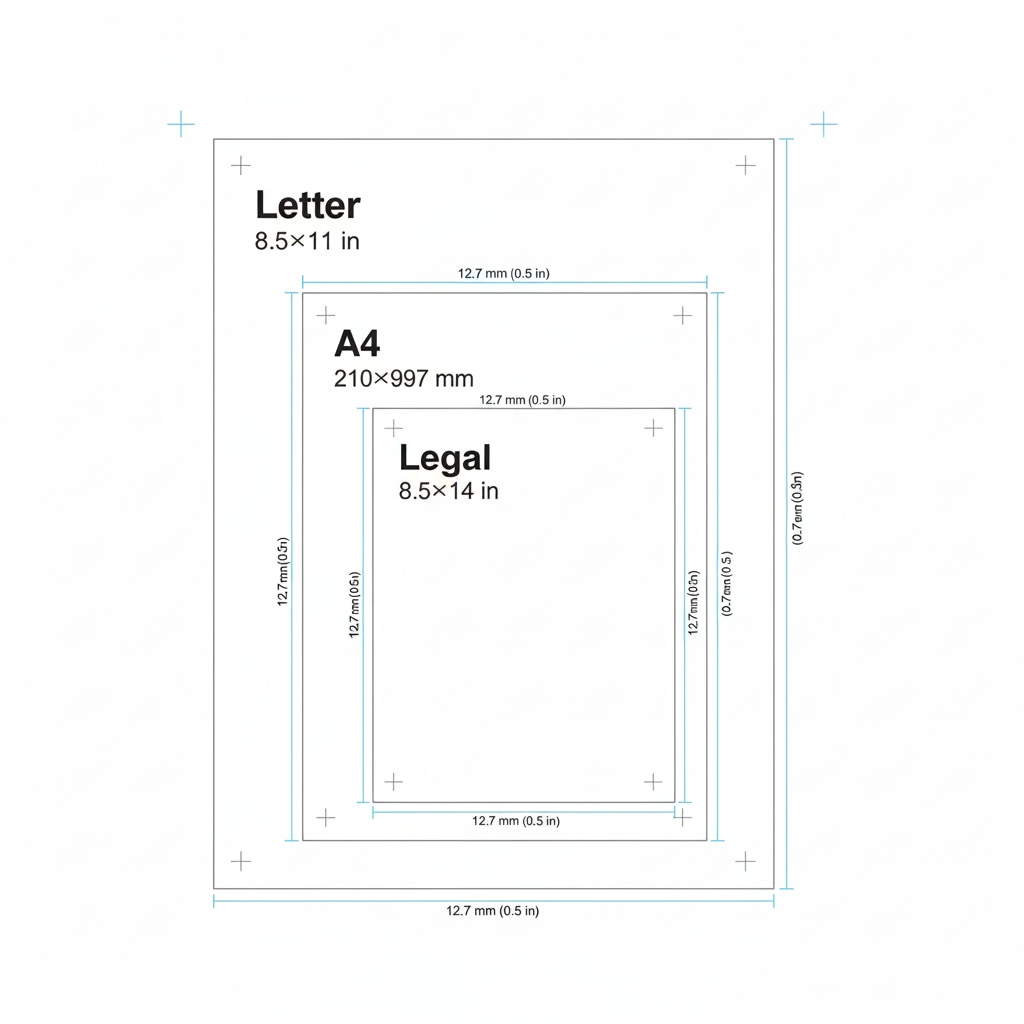

The formats, precisely defined: Letter, A4, Legal

Clarity starts with exact dimensions and tolerances.

Letter: 8.5 × 11 in (216 × 279 mm). U.S. and Canada default for office documents.

A4: 210 × 297 mm (~8.27 × 11.69 in). The ISO 216 standard is used across most of the world.

Legal: 8.5 × 14 in (216 × 356 mm). Used in certain legal/government workflows in North America.

Tolerances and margin implications

Paper is manufactured within small tolerances; printers also have mechanical registration variances. Safe, universal templates assume a minimum body margin of 12.7 mm (0.5 in) on all sides for Letter/A4 interchange. Elements that sit closer to the edge risk clipping when formats cross.

Software defaults

Operating systems: Regional settings influence the default paper size in drivers. A U.S. image often assumes Letter; an EU image assumes A4.

Office suites: Word processors and presentation tools inherit document defaults from regional templates.

PDF: PDF preserves page size explicitly, but print dialogs can “fit to printable area,” which quietly scales content and distorts brand elements.

When Legal actually matters.

A legal-length paper is appropriate when jurisdictions require forms that cannot be altered without compromising their official content. Otherwise, Legal should be treated as a controlled exception to avoid creeping complexity.

Risk analysis: what goes wrong when standards diverge

Template reflow and pagination breaks

A4 is taller and narrower than Letter; a layout designed tightly for one can spill to an extra page on the other. Bulleted lists, table rows, and footers are standard breakpoints. Even a single additional page adds cost and degrades readability.

Device behavior and stock selection

Auto-tray selection: If the driver requests A4 but only Letter is stocked, devices may hold the job for manual confirmation, causing queues.

Duplex performance: Heavier stocks (e.g., 24 lb / ~90 gsm) reduce show-through and curling during double-sided runs; using a light stock for duplex jobs often results in reprints.

Registration and skew: A slight dimensional mismatch increases the perception of poor quality on forms and labels related to skew.

Logistics and emergency purchasing

Regional sites that face format mismatches often place last-minute orders outside of contract channels. These purchases usually result in inferior pricing, inconsistent brands, and variable quality, which exacerbates print defects and returns.

Decision framework: choosing a global baseline (and approved exceptions)

A robust standard respects geography while privileging simplicity. Multinational teams use the following framework to reach a single source of truth.

Declare a global default.

Organizations with a predominantly U.S./Canada footprint typically select Letter.

Organizations whose headcount and customer deliverables are majority outside North America usually choose A4.

Define exception classes.

Regulatory: Government-issued forms that prescribe Legal or a fixed ISO size.

Customer-mandated: Contracts or templates supplied by clients that must not be altered.

Legacy systems: Line-of-business tools that generate fixed-size outputs pending roadmap remediation.

Assign ownership and approval.

A cross-functional working group (procurement, IT print services, facilities, legal) reviews and approves exceptions with an explicit sunset or review date.

Create a document taxonomy.

Global templates (letters, proposals, invoices) adopt the global default.

Local templates record their exception rationale and live in a controlled library.

Establish reflow-safe rules.

Minimum margins and font stacks that preserve pagination when a document is opened under different locale defaults.

Prohibit text boxes anchored to the page edge; favor flow-aware styles.

Device and workflow compatibility across Letter, A4, and Legal

Printer/MFP configuration

Default size and region packs: Drivers on managed endpoints should ship with the organization’s global default size and region settings.

Auto-tray and size mismatch prompts: Disable user prompts where possible and enforce “scale to fit” only for controlled, low-risk document classes; otherwise, block the job and surface a clear message to the help desk.

Duplex and orientation: Lock duplex defaults for classes of documents where two-sided printing is safe; specify long-edge vs short-edge binding per template type.

Template governance

Master templates: Maintain centrally with version control. Each new version is validated for reflow on both Letter and A4.

Office macros and add-ins: Use scripts to set document page size and margin styles on creation.

PDF creation: Embed page size and disallow auto-scaling in shared print profiles used by finance, legal, and sales.

Print server and queue policy

Queue segmentation: Separate queues by paper size only where the organization endorses multiple sizes in the same site.

Secure release: Follow-me print solutions should retain the page size attribute to avoid accidental re-routing to incompatible devices.

SKU standardization: weights, GSM, brightness, and packaging

The SKU set should be minimal yet cover 95% of day-to-day needs.

Weights and GSM conversions

20 lb bond ≈ 75–80 gsm: Everyday mono printing, short internal use, single-sided workflows.

24 lb bond ≈ 90 gsm: Double-sided output, dense charts, mixed mono/color with reduced show-through.

Heavier specialty stocks (≥100 gsm): Client-facing packets, covers, or forms requiring rigidity.

Brightness and surface

Brightness 92–94: Balanced readability and cost for volume work.

Brightness 96+: Higher contrast for dense content or scanning; evaluate against potential toner/ink behavior on long runs.

Surface finish: Uncoated multipurpose for mixed fleets; coated or inkjet-optimized only for specific devices after validation.

Archival and sustainability attributes

Acid-free and lignin-free for long-term records.

Recycled content targets can be set per region, aligned to policy and availability.

Certifications such as FSC/PEFC are recorded at the SKU level to ensure consistent sourcing.

Packaging and labeling

Ream, case, carton, and pallet standards define count per unit, strap type, and barcoding conventions.

Labels should include page size, weight (in pounds and grams per square meter), brightness, and region code to reduce mis-shelving.

Supplier model and service levels for multi-region coverage

Sourcing architecture

Prime supplier + regional backups: A single strategic partner where possible, with pre-vetted alternates for regions where availability or lead times vary.

Substitution matrix: For each approved SKU, define acceptable alternates by manufacturer code and equivalency notes (size, weight, brightness, recycled content).

Service level contours

Delivery windows: Site-specific delivery days and cutoff times, taking into account local holidays and observances.

Damage and moisture controls: Clear thresholds for carton moisture damage, crushed corners, and claims procedures.

Palletization and freight: Specify pallet height limits, stretch-wrap standards, and corner protection to reduce in-transit deformation.

Price stability mechanisms

Indexation rules: Where contracts use pulp indices, document review cadence, and caps.

Spot-buy guardrails: Conditions under which urgent buys are allowed, with documentation to preserve auditability.

Rollout plan: change management without disruption

A clean transition replaces ad-hoc purchasing and incompatible defaults with a predictable standard. The plan below assumes a global Letter or A4 baseline with controlled exceptions.

Baseline assessment (2–4 weeks).

Inventory formats and weights at each site.

Enumerate templates by department and page size.

Capture driver defaults and print server policies.

Policy drafting (2 weeks).

Document the global default, exception classes, and approval workflow.

Specify the SKU list, substitution matrix, and labeling conventions.

Pilot implementation (4–6 weeks).

Select two to three representative sites (different regions, device fleets, and user profiles).

Migrate templates, update drivers, and consolidate SKUs.

Monitor reprint rates, hold-queue prompts, and user feedback.

Progressive rollout (8–12 weeks).

Sequence remaining sites; align with local inventory wind-down to avoid write-offs.

Provide concise, quick-reference guides at the device and in the company knowledge base.

Track escalations and adjust exception rules if a legitimate local constraint arises.

Stabilization and governance (ongoing).

Quarterly reviews of exception inventory and template library.

Annual vendor performance reviews against delivery quality and stock substitution accuracy.

Environmental controls and quality assurance

Paper is hygroscopic; quality depends on storage and acclimation.

Storage climate: Target relative humidity 40–55% and temperature 20–24 °C (68–75 °F). Avoid direct floor contact; use sealed bins in open offices.

Acclimation: Allow cases to equilibrate to print room conditions before opening; cold deliveries “sweat,” increasing curl and jams if used immediately.

Sampling: For each pallet or large shipment, select a small batch to run through a standard duplex job and record observations of curl, show-through, and misfeed.

Escalation: Define the threshold for defect claims (e.g., number of misfeeds per 1,000 sheets on validated devices) and the documentation required for supplier corrective actions.

Cost model and operational metrics

A standard should justify itself with stable operations and predictable spend. The following measurement approach ensures that the analysis remains practical and repeatable across sites.

What to track

Reprint rate (%): Reprints divided by total jobs, segmented by template class.

Jam incidents per 10,000 pages: Pulled from device logs or print management software.

Show-through/duplex defects: Periodic visual inspection scores for dense documents.

Stockouts and Emergency Buys: Site-Level Count and Cause Analysis.

Inventory turnover (days): By format and weight to expose slow-moving exceptions.

Freight per case/pallet: Before vs after consolidation.

How to compare before vs after

Record a baseline month before standardization at pilot sites.

After rollout, compare three-month rolling averages to smooth seasonality.

Attribute reductions in jam incidents and reprints to a combination of SKU consolidation, driver defaults, and template governance—the standardization triad.

Watch for displacement effects (e.g., fewer reprints but higher freight due to centralized purchasing) and tune reorder points accordingly.

Governance: keeping the standard durable

Sustaining the gains is a matter of ownership and cadence.

Stewardship: A named group (print services, procurement, facilities, and legal) owns the standard, approves exceptions, and publishes changes.

Change control: Template updates follow a lightweight request → review → publish flow, with cross-format tests baked in.

Transparency: Sites can view the current SKU list, approved alternates, and exception statuses in a shared, read-only space.

Education: Short, device-side signage and intranet guides reduce local improvisation and keep new staff aligned.

Continuous review: Annual validation of the global default remains appropriate; evaluate whether exceptions can be retired.

Putting standardization to work across regions

A practical global policy reduces noise in every layer of the print ecosystem: clearer templates for authors, predictable behavior on mixed fleets, leaner inventories for facilities, and steadier service levels for operations teams. Whether Letter or A4 is chosen as the baseline, disciplined exceptions and explicit governance keep the standard adaptable without reintroducing chaos. The result is fewer surprises, lower operational drag, and documents that look the same—wherever they are created or read.